Optical industry

The optical industry relies on advanced technologies and equipment to produce and use high-quality optical products.

Each of these tools has a specific role and contributes to improving the testing, measurement, alignment and assembly processes in the optical industry.

The benefits of optical instruments:

Testing and quality verification: Optical instruments enable quality testing and verification of optical components and optical systems. They are used to measure parameters such as optical accuracy, resolution, magnification power, illumination uniformity and others.

Precise measurements: Optical instruments provide precise measurements of various optical characteristics such as distances, angles, light intensity, refractive index, thickness and others. These measurements are essential for characterising and evaluating the performance of optical components.

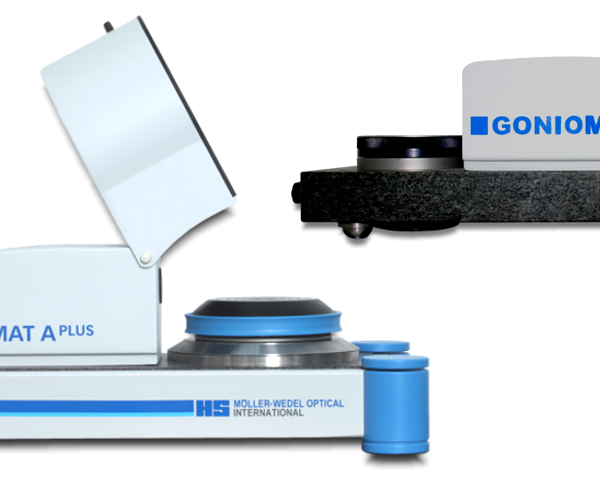

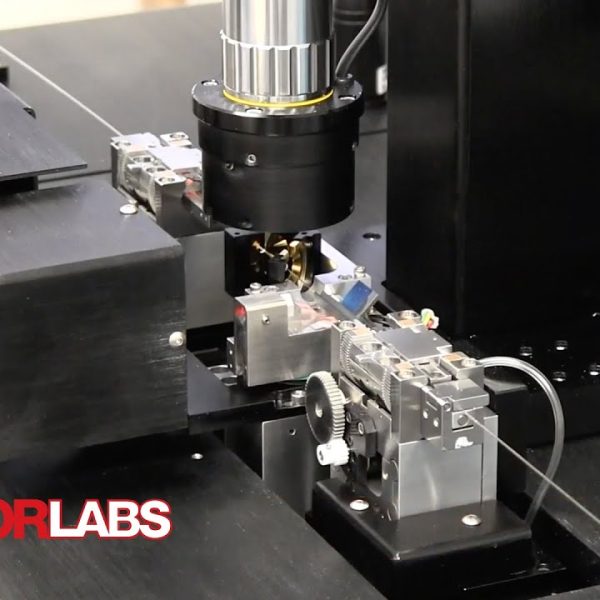

Alignment and assembly: Optical instruments, such as goniometers, autocollimators and alignment systems, allow precise alignment of optical components in a system. This is a crucial step in ensuring the optimal functioning of the optical system.

Optical profile characterisation: 3D optical profilometers are used to measure and map three-dimensional profiles of optical surfaces. These measurements are important for quality control and performance evaluation of optical components.

Testing and simulation of illumination conditions: Solar simulators and test systems allow the performance of optical systems to be tested under illumination conditions similar to solar conditions. They are used in the photovoltaic industry and other optical applications.

Development and innovation: Optical instruments facilitate development and innovation in the optical industry. They enable researchers and engineers to explore and test new optical technologies and applications.

Quality control and conformity assurance: Optical instruments are used to control the quality of optical components and ensure compliance with specifications and industry standards.

Product categories

- 3D Printing

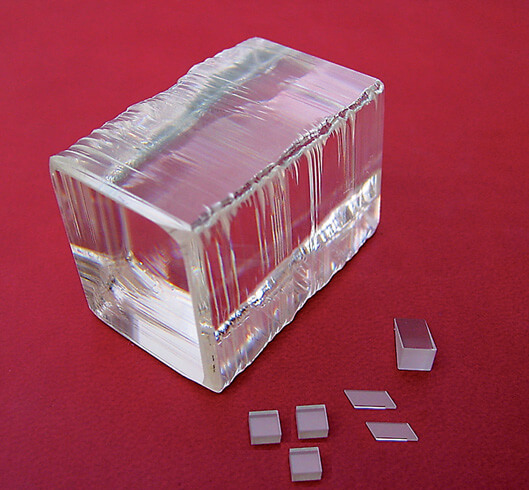

- Advanced Scientific Materials

- Analytical Instruments

- Climate monitoring systems

- Custom Solutions

- Deburring machines for deburring and edge rounding

- FLANGING - MANDRELLING

- FORMING AND FINISHING

- Forming tools

- Laboratory Equipment

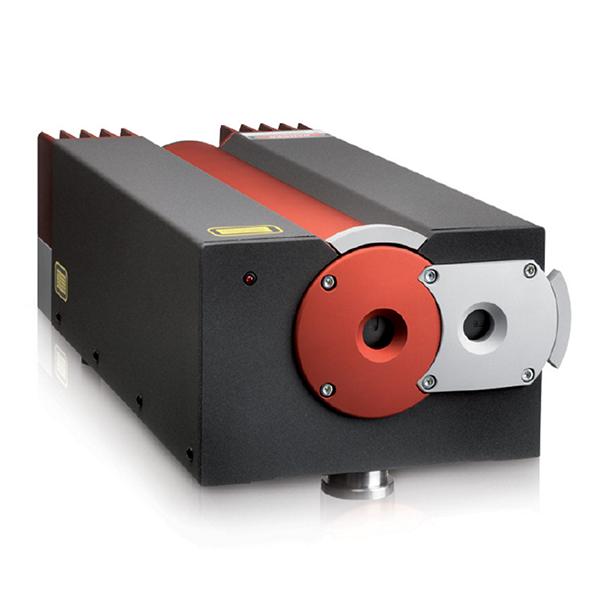

- Laser systems

- Lasers

- Light sources

- METAL JOINING - CLINCHING

- Microscopy and accessories

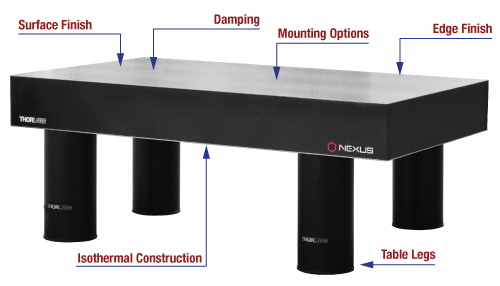

- Optics and Optomechanical Components

- ROTO - FORMING

- Scientific cameras

- Spectrometers

- Cristale laser

- Numaratoare de particule