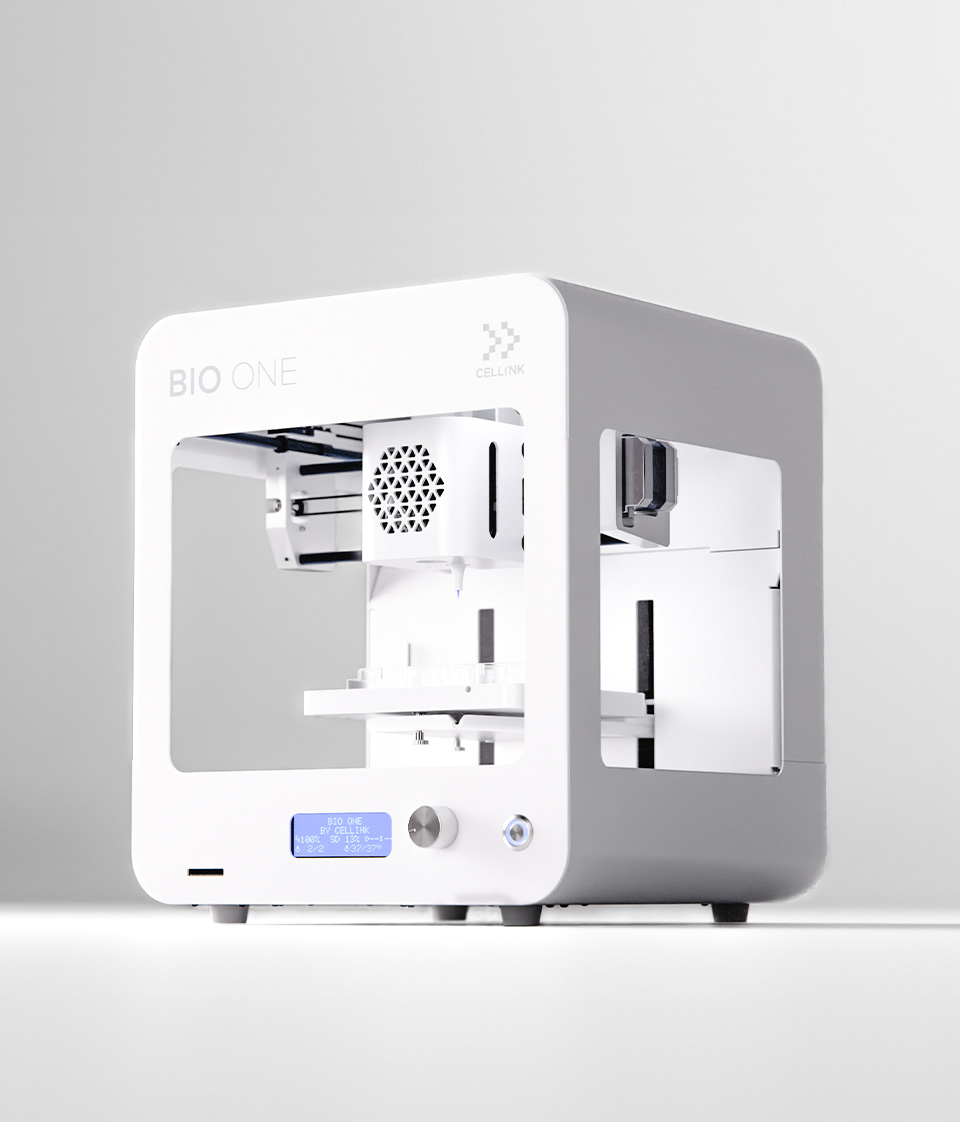

BIO ONE 3D bioprinter | CELLINK

Unlock the World of 3D Cell Culture

Eliminating the barriers to 3D cell culture

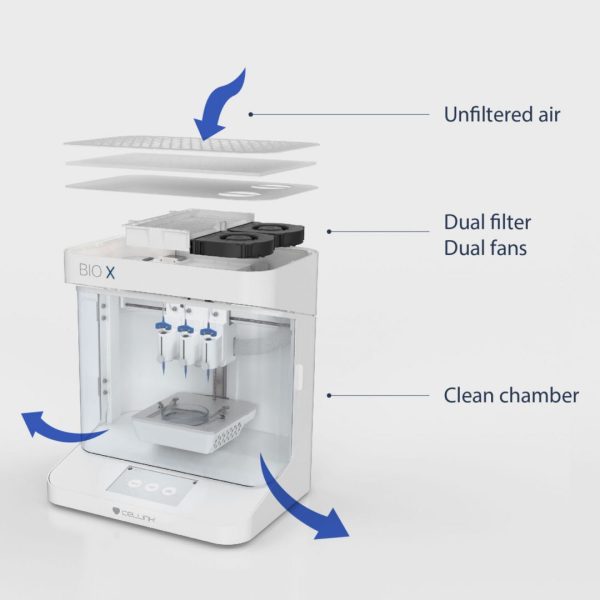

With exceptional cooling capabilities, precision syringe-based extrusion and an intuitive, easy-to-use desktop software in DNA Studio Core, the BIO ONE brings a new level of ease in the transition to 3D cell culture.

Designed for printing temperature-sensitive materials, the BIO ONE enables scientists to develop 3D models that replicate in vivo environments, contributing to accelerated discoveries. BIO ONE is an instrument that empowers researchers regardless of previous knowledge in constructing more physiologically relevant models, while reducing cost and ensuring more accurate data.

Features and Benefits:

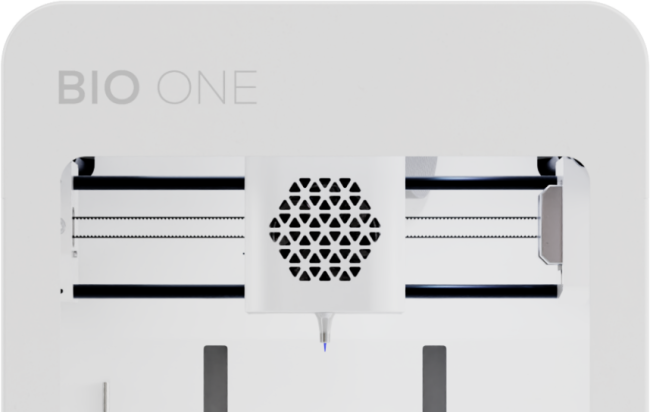

Cooling capabilities

Rapidly cool the BIO ONE printhead down to 0 °C and maintain the temperature throughout the print. With a novel design, ensure temperature stability till the tip of the nozzle from start to finish.

Material flexibility

The BIO ONE is designed to be an open material platform, meaning that users can load any material into a syringe and dispense it, including temperature-sensitive materials like collagen.

Precision extrusion

Enable total control over your print with the high-precision mechanical extrusion of the BIO ONE. The mechanism boasts an impressive 0.1 μL volume step.

Heated printbed

Extend construct stability and cell viability for heat-responsive materials through thermal crosslinking, using the built-in printbed heating ranging from RT – 65 °C.

Maximized reproducibility

Enable highly reproducible structures with limited print-to-print variation and human error, by both leveraging the precision and by saving your protocols to the software.

DNA Studio Core

Powered by DNA Studio Core, the BIO ONE has ease-of-use as its core principle, which makes it easier than ever to enter the world of 3D cell culture.

Technical Specifications:

The BIO ONE is equipped with a mechanically driven syringe-based printhead, ensuring precision and reproducibility in 3D model development. Mechanical extrusion offers superior accuracy when compared to pneumatic extrusion.

A 0.1 μL volume step and mechanical extrusion through a syringe for enhanced precision and reproducibility.

Rapid and stable cooling of the entire printhead, maintaining any temperature from RT to 0 °C throughout the print.

Excellent control and accurate printing of both low and high viscous biomaterial with consistent flow rates.

Minimizing material waste by giving you the ability to precisely control the exact material volume of your print.

3D bioprinting technology : Temperature controlled, syringe-based extrusion

Printhead volume : 2.5 mL*

Theoretical volume unit step : 0.1 µL

Build volume : 130 mm x 80 mm x 50 mm

Photocuring system : 405 nm LED

Operating temperature range : 15 – 30 °C

Power supply : Input: 100-240VAC, 50/60Hz, 2.0A Output: 24VDC, 6.67A, 160W

Outer dimensions (D x W x H) : 325 mm x 370 mm x 380 mm

Weight : 15 kg

| Manufacturer | |

|---|---|

| Applications / Industries | , , , , , |

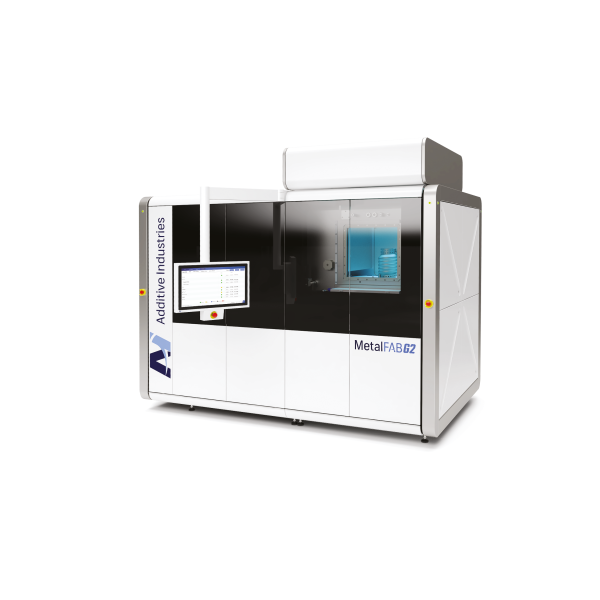

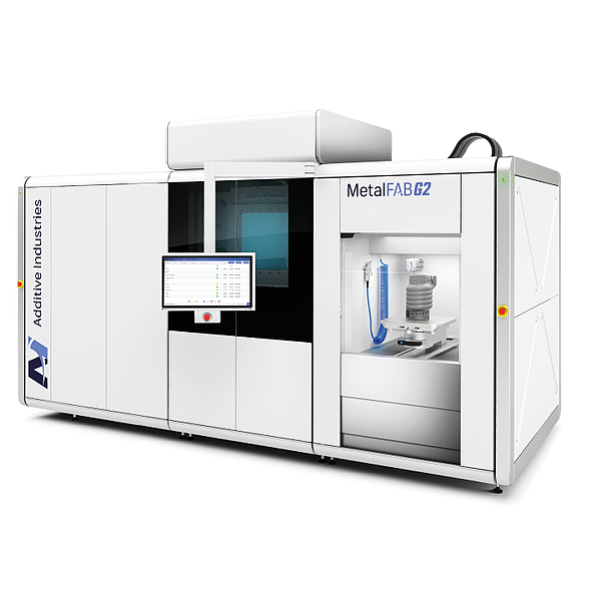

Related products

DIDN'T FIND WHAT YOU WERE LOOKING FOR?

Our team is here to help you! Call us or leave us a message and an Apel Laser consultant will be happy to answer your questions and find personalized solutions for you.