Blog

Eye Safety in the Presence of Lasers: Biological Risks and Technological Solutions

Why is laser radiation dangerous?

The ‘light’ from powerful lasers can be concentrated to power densities (power per area or watts/cm2) that are high enough to evaporate tissue, metal or ceramics. In the medical field laser radiation is used to remove tattoos or to cut human tissue. These examples show a range of applications which require high power lasers and as such there is a high potential risk of accidental illumination of the user. Because the eyes are much more sensitive to light they are at increased risk. In fact, it is possible to cause irreversible ocular injury with just one glance into a direct or reflected laser beam even at lower power output levels.

Physical background

Wave trains of any given laser radiation have a fixed relation to time and space (coherent) and are all of nearly the same wavelength (monochromatic). Laser light can travel over great distances as a nearly parallel beam (collimated). All of this means that the power that can impact an area such as the eye is independent of the distance to the radiation source. Imagine a laser pointer with a beam spot that remains about the same size over great distances. If you compare a thermal source of radiation like a light bulb with a laser you will observe several differences. The light bulb emits light over a very broad spectrum of wavelengths with no specific direction of dispersion. The power of the bulb that may reach the eye decreases with distance because the bulb radiates in all directions (see picture). When comparing a light bulb with a laser, both emitting 1 W optical power, and if there is a 1 meter distance between our eyes and the light source, then the quantity of light coming from the laser would be increased by a factor of 100,000 compared to the light quantity from the bulb (this assumes a normally dilated pupil diameter of 7 mm – i.e. eyes adapted to darkness).

Focussability

In addition to the quantity of light that can hit the eye the high focus ability of the coherent laser light is another danger. While the bulb creates an image on the retina of approximately 100 μm, the laser light is reduced to a spot of just a few micrometers (~ 10 μm) in diameter. A physicist would say that the bulb produces incoherent light. Therefore, the light quantity of a laser that hits the eye is concentrated on a much smaller spot. The power density (power per area or watts/cm2) resulting from this concentration may be sufficiently high, so that any tissue in the focus will be heated up and very quickly destroyed.Since the fovea (responsible for sharp central vision and located on the retina) also has a size of just a few micrometers, it is possible to lose one’s eyesight by one single laser pulse.

Technology

Due to the unique characteristics of laser radiation (i.e. coherent, collimated and monochromatic) there is an increased danger to the eyes. To protect the humans’ eyes special optical filters for laser safety glasses or laser safety windows are used. Since laser light has a specific wavelength which is dependent on the laser active medium that emits light, protective filters that match the wavelength and power of the specific source of laser radiation are needed. These filters transmit “normal“ light, viz. visual light, beyond the particular laser wavelength. The filters coevally feature a block function with an ±30° vertical defined incidence angle.

Plastic filters and technology

In order to meet the requirements of its customers in all fields of laser technology and to be able to offer high quality and norm consistent acrylic laser safety products even for new applications laservision is continuously developing, producing and testing in close cooperation with its mother company uvex-safety and other partners new materials, manufacturing technologies and absorber colours. Raw materials for several products are therefore processed in house and produced in the appropriate manner. At the same time an intensive design development takes place in order to continuously improve wearing comfort and features of our eyewear. Within the area of plastic windows laservision was able, for the first time ever, to develop windows at a size of 3000mm x 2000mm for laser safety at a wavelength range 1064nm.

Glass filters and technology

Since almost four decades laservision broads experience in the field of glass processing for laser safety eyewear. Lamination of different glass types or filter materials allows to offer customized protection filters with individually designed protection ranges for different wavelength. On the other hand lamination with neutral glass ensures increased thermal stability and break resistance as a particular requirement with larger cabin windows. A large number of laservision glass filters are also available in a curved shape (basis curve). These filters while being laborious to make provide a very good field of view and offer the user a high level of wearer comfort.

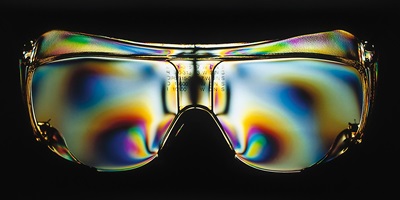

Reflection filters and coating technology

Due to the long standing experience and research in the field of coating technology laservision is able to produce reflective coatings on glass as well as on acrylic substrate in its own coating facility. In the case of a laser hit most of the laser energy is reflected from the filter, the protection is highly independent of the chosen substrate. Therefore with this technology it is possible to achieve the kind of high protection levels with plastic filters that have previously only been available with glass filter technology. Reflective filters offer improved colour vision as required in most medical applications. The combination of coatings with absorbing filters allows a nearly unlimited number of variations for all possible wavelengths.

In conclusion, eye safety in the presence of lasers is a major concern, given the concentrated and focused nature of laser radiation. The biological risks associated with laser exposure are significant, and the effects can be devastating to the eye. However, technology has advanced considerably in the development of protective solutions, including safety glasses and laser protection windows, which filter and block dangerous laser radiation. Laservision and other specialized companies continue to innovate in this field, developing new materials and technologies to ensure optimal eye protection against the biological risks of laser radiation. With the proper use of protective equipment and safe work procedures, the biological risks associated with laser exposure can be minimized, ensuring a safe and healthy work environment for all involved.