Blog

Advancing the Adoption of Biofluorescent Particle Counting

Read about the evolution of the pharmaceutical manufacturing industry working groups that are now collaborating to advance the adoption of the use of biofluorescent particle counters (BFPC) as quickly as possible to remove risk and increase pharmaceutical manufacturing capabilities.

Regulatory authorities continue to encourage the use of alternative and rapid microbiological methods (ARMM). The recent update to EU GMP Annex 1 is just one example of this. Despite this encouragement, adoption remains very challenging. Guidance documents have improved in regards to qualitative, rapid methods, but continue to offer minimal direction for quantitative, alternative methods. Therefore, the path to implementation is left to the early adopters to find. If they chose to work independently, multiple paths may be followed. This leaves regulators unclear on what is appropriate and could extend the time to reach acceptance. The preferred alternative is to have early adopters work together to determine the industry best practice and speak to regulators with a single voice.

Fortunately, the pharmaceutical companies interested in adopting the use of biofluorescent particle counters (BFPC) have chosen the latter. These companies see the value in advancing this technology as quickly as possible to remove risk and increase manufacturing capacity. The only way to do that is by working together. This effort has taken the form of working groups that have remained committed and productive.

A Brief History of BFPC Working Groups

TSI, along with other BFPC equipment manufacturers, started the Process and Environmental Monitoring Methods (PEMM) working group in 2014. Some work was done early on, but the group did not remain active and stalled until 2018 when increased interest in the technology prompted an effort to revive the group. Some of this renewed interest was the result of another working group, the BioPhorum Fill Finish Alternative and Rapid Micro Methods (ARMM) BFPC Team. This group comprised of representatives from several large pharmaceutical companies, was founded in 2017, and actively began to determine the feasibility of using BFPC to monitor in Grade A. The PEMM group expanded rapidly at this time, adding members from pharmaceutical companies, including some that were also in the BioPhorum group, and consultants.

The BioPhorum and PEMM groups, while aware of each other, worked independently at this time. BioPhorum collected data and published articles in the Parenteral Drug Association (PDA) Journal. PEMM also published some articles and opened a dialogue with the Food and Drug Administration (FDA) Emerging Technology Team. There were also two other working groups at this time that were actively working toward similar goals, the Online Water Bioburden Analyzer (OWBA) working group and the Kilmer Community Rapid Microbiology Methods working group. While there was significant crossover between these groups, it was decided that a more formal association should be established to ensure alignment and avoid duplication of work. This led the groups to hold their first summit in 2021.

Resulting from the summit, it was concluded that working collaboratively would be optimal for achieving shared goals, and thus the Modern Microbial Methods (M3) Collaboration was formed. While the individual working groups all remain active, the bulk of the efforts are now being performed through M3. M3 is comprised of a steering committee and three subgroups. The group’s first published article in the PDA Letter provides a roadmap for an initial evaluation of BFPC technology. That was followed with an article in the PDA Journal on the challenges of implementing BFPC that served as an introduction to a series of additional articles. As of today, this has included an article on the non-equivalency of the auto fluorescent unit (AFU) and the colony-forming unit (CFU), with articles on validation and baseline/establishing alert and action levels expected to be published in the near future. Additional to this series, an opinion piece outlining the justification for not needing to attempt to perform an identification in the event of a Grade A excursion was published in the PDA Letter.

BioTrak User Group Meetings

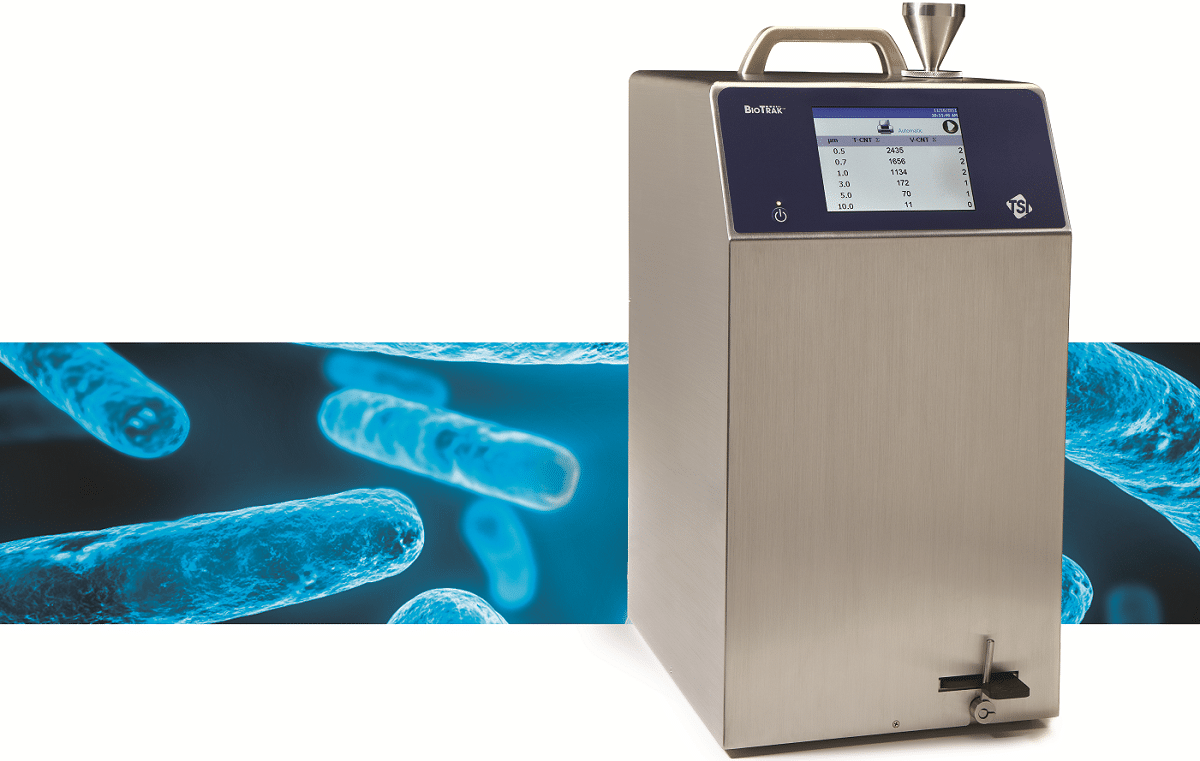

Outside of the working groups described above, there has been an effort by the early adopters of the BioTrak™ Real-Time Viable Particle Counter, a BFPC instrument for viable air testing, to come together to seek alignment and specifically address the challenges involved in validation and implementation. These companies understand that environmental monitoring is not what they are competing over. Instead, it is in their best interests to work together to establish the best practices for BFPC use and ensure they have consistent messaging when communicating with regulators. To date, five user group meetings, with ever-growing attendance at each, have taken place. These meetings are largely driven by the users with open, highly productive discussions.

An Exciting Future of BFPC Technology

What began as an effort by equipment manufacturers to convince pharmaceutical industry stakeholders in the value of their instruments, has evolved into a large community that believes BFPC is a technology that offers great advantages over traditional microbiological monitoring methods. While the equipment manufacturers remain highly involved in these efforts, now that the value of the technology is widely accepted, their role has become one of providing technical expertise in these highly active working groups. Due to these collaborative efforts, the pharmaceutical industry is now seeing a paradigm shift in technology through the large commitment of time and energy from representatives whose companies see BFPC as the future for monitoring their Grade A areas. These efforts are establishing best practices to pave the way for widespread adoption and acceptance of a technology that is proving to change the scope of pharmaceutical manufacturing to move the industry forward.

The adoption of biofluorescent particle counting (BFPC) represents a major step for increasing safety and efficiency in pharmaceutical production. Through the collaboration between regulatory authorities, manufacturers and users, active working groups, such as BioPhorum and PEMM, contribute to the development of best practices and to the acceleration of BFPC acceptance. This innovative technology allows rapid monitoring of Class A environments, reducing risks and supporting a significant paradigm shift in the industry. Joint efforts ensure a coherent and efficient implementation, opening the way to the future of pharmaceutical production.