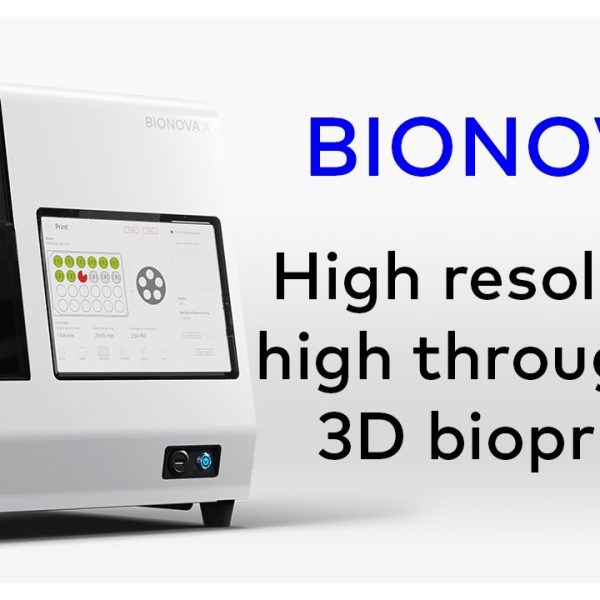

BIO CELLX 3D Biodispenser | CELLINK

The high-throughput, fully automated biodispensing solution that leverages BIOPOD (bioprinting on demand) technology with pre-set and pre-validated protocols to bring the power of 3D cell biology to your benchtop. The easy-to-use biodispensing system allows you the time and energy to focus on your research.

Features & Benefits:

Precise & reproducible: The BIO CELLX is a high-precision positive displacement extrusion system. This technology provides reproducible results every single time – regardless of the dispensed material.

Uncompromised sterility: CELLINK’s fully enclosed, proprietary Clean Chamber technology, combined with a patent pending de-lidding solution, ensures the sterility of the entire workflow when working on a benchtop in a laboratory environment.

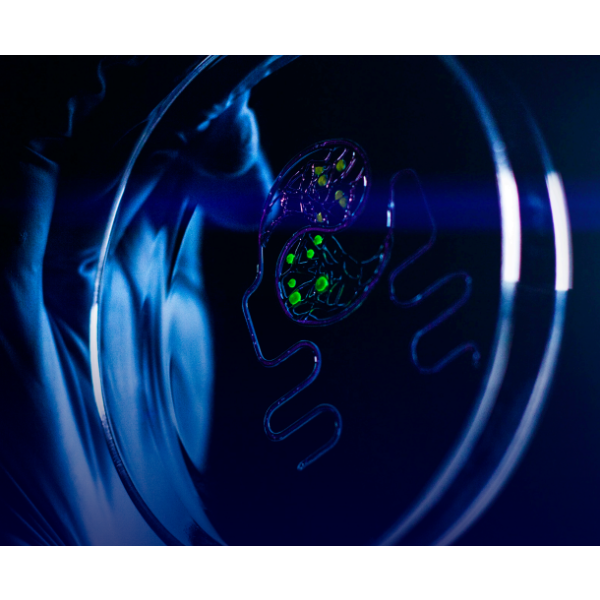

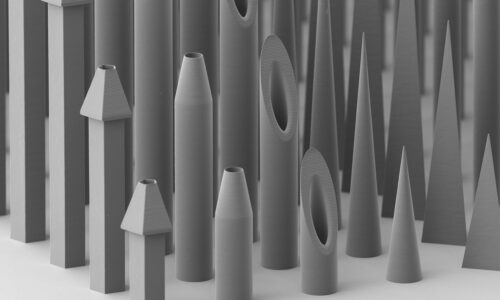

Flexible, validated geometries: Developed by scientists for scientists, pre-validated protocols ensure consistent and reproducible 3D model generation, guiding users through every step of the workflow, from material selection to dispensing to downstream analysis methods.

Automated Calibration:To achieve an industry-leading positional accuracy, a sensor suite measures the position of each of the dispensing orifices in relation to the position of the vessel. An algorithm compensates any inaccuracies to ensure the precise position of the dispensed model.

Nozzle priming, now with AI:For the first time ever, ensure flawless dispensing courtesy of artificial intelligence-powered nozzle priming, with onboard bubble detection for consistent cell-laden constructs.

No modeling required: Thanks to the variety of 3D models built into BIO CELLX Studio there’s no longer a need to spend time modeling in CAD software.

Technical Specifications:

Outer dimensions (L x W x H), mm: 765x580x555.

Build volume, mm: 125x85x38.

Build surface compatibility: Multi-well plates 6-well to 384-well, Petri dishes.

Theoretical resolution XY, µm: 3.

Theoretical layer resolution, µm: 1.5.

Material mixing stations: 3.

Bioink max volume, mL: 3.0.

Cell media max volume, mL: 2.0.

Source fluid temperature range, °C: 0-60.

Volume unit step, µL: 0.1.

Theoretical minimum droplet size, µL: 0.2.

Printbed temperature range, °C: 0-60.

Photocuring system, nm: 365, 405, 485, 520.

Filter class, chamber flow: HEPA 14.

UV sterilization: UV-C (275nm).

Calibration: Automatic.

User interface: Tablet.

Connectivity: Ethernet, WiFi.

| Manufacturer | |

|---|---|

| Applications / Industries | , , , |

Related products

DIDN'T FIND WHAT YOU WERE LOOKING FOR?

Our team is here to help you! Call us or leave us a message and an Apel Laser consultant will be happy to answer your questions and find personalized solutions for you.