EdgeBreaker® 6000 | ARKU

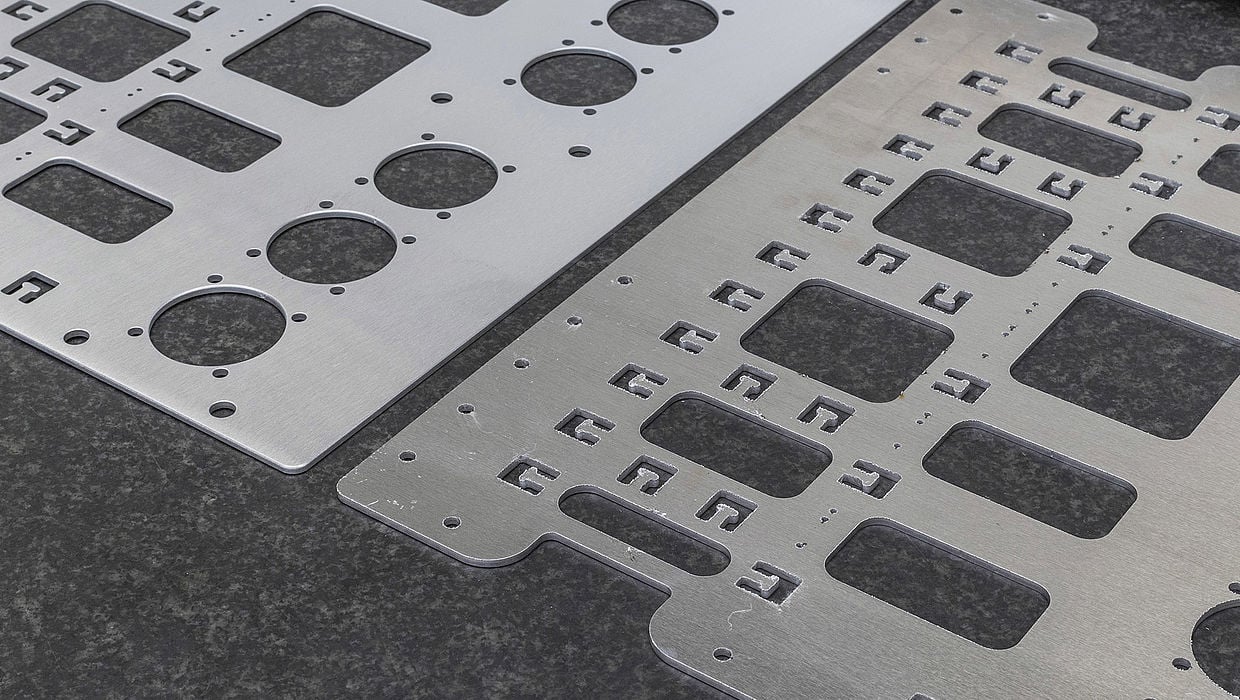

The EdgeBreaker® 6000 versatile deburring machine is specifically designed for the complete processing of materials after punching and laser cutting. This includes deburring, edge rounding and surface finishing. The distinctive rotary brush system ensures a uniform edge rounding result and a radius of up to 2 mm. Thanks to the vacuum belt, even small parts can be processed. With the grinding belt, rotary brushes and finishing belt, the EdgeBreaker® 6000 deburr machine is the most versatile deburring machine in the family of EdgeBreakers®.

Resources:

Features & Benefits:

Application versatility.

The EdgeBreaker® 6000 is capable of processing a broad range of part sizes. From small to large parts, punched or laser cut – this machine is capable of processing your entire range of parts. Surface finishing required as well? No problem. This is the best all-around machine for a fabricator who want to be prepared for the requirements of tomorrow.

Unmatched rounding up to 2 mm.

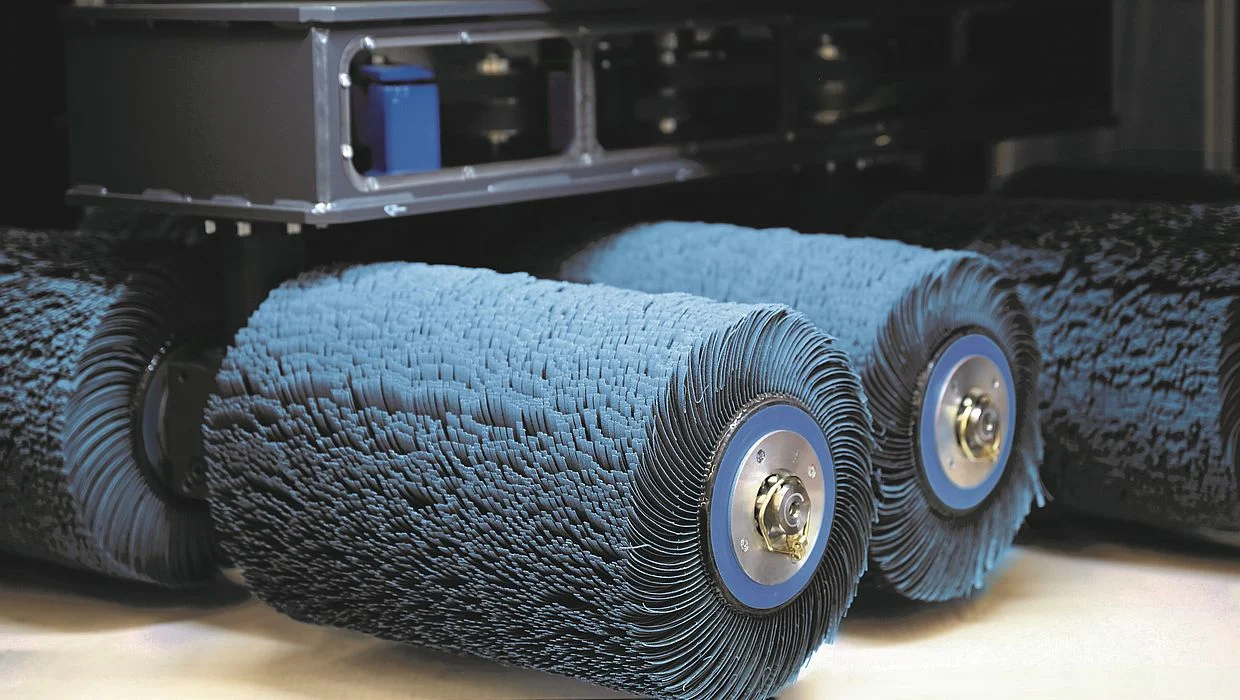

The most distinctive unit in the EdgeBreaker® 6000 is the rotary brush system. It can achieve a unique rounding result along the edges. The brushes rotate in alternating directions, so you can achieve a consistent result on the inner and outer contours of your parts. If necessary, a radius up to 2 mm is possible.

AI-assisted machine adjustment for best processing results.

The ARKU Wizard is an intelligent software that automatically adjusts the processing settings of the EdgeBreaker® 6000 to achieve the best final results. This means operators no longer have to figure out the ideal processing for sheet metal via trial and error.

User-friendly.

The touchscreen HMI is truly intuitive. This feature enables even new operators to quickly and easily setup the machine. It can even give you guidance on operating and maintenance. For efficient processing and minimal operator error.

Quick changing of abrasive media.

The EdgeBreaker® 6000 was designed with the goal of keeping downtime to a minimum. All abrasive media of the various processing units can easily be changed, and the inside of the machine is purposefully accessible for faster routine cleanings and maintenance.

Automatic calibration / media wear compensation.

For consistent results, it’s important to know the remaining length of the abrasive media. This is crucial to producing repeatable, high-quality parts. The EdgeBreaker® 6000 measures the remaining length of the abrasive media and automatically compensates for the wear, further minimizing operator error.

Technical Specifications:

Processing: single-sided, dry.

Material thickness: 1,0 – 25 mm.

Max. working width: 1300 mm.

Weight: approx. 6.500 kg.

Dimensions: 2100 x 4200 x 2350 mm.

Min. part dimensions: 50 x 50 mm (2 x 2 inch).

Feed rate: 0.2 to 8 m/min. (0.7 to 26 ft/min.)

| Manufacturer | |

|---|---|

| Applications / Industries | , , , , , , |

DIDN'T FIND WHAT YOU WERE LOOKING FOR?

Our team is here to help you! Call us or leave us a message and an Apel Laser consultant will be happy to answer your questions and find personalized solutions for you.