Aluminium Alloys | Goodfellow

Alloys are mixtures of a metal with other elements, the precise combination being governed by the required properties. Alloys are generally considered to be metallic in nature i.e. they have good thermal and electrical conductivities). Alloys can be manufactured by various routes, the most widely used being to melt the constituents together and to cool the resultant mixture to form a single or multi-phase solid.

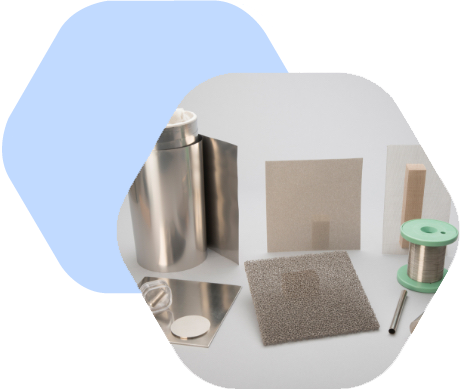

Resources:

Features & Benefits:

Diverse Alloy Options: Goodfellow offers a wide range of aluminum alloys, including various compositions and grades, to suit different applications and industries.

High Strength-to-Weight Ratio: Aluminum alloys are known for their excellent strength-to-weight ratio, making them ideal for lightweight structural components and applications where weight savings are crucial.

Corrosion Resistance: Many aluminum alloys exhibit good corrosion resistance, making them suitable for outdoor and marine applications.

Thermal Conductivity: Aluminum alloys have excellent thermal conductivity, making them valuable for heat exchangers, cooling systems, and other thermal management applications.

Machinability: Some aluminum alloys are easily machinable, allowing for precision manufacturing and ease of fabrication.

Weldability: Aluminum alloys can be welded using various methods, offering versatility in joining techniques.

Electrical Conductivity: Certain aluminum alloys are known for their high electrical conductivity, making them useful in electrical and electronic applications.

Recyclability: Aluminum alloys are highly recyclable, contributing to sustainability efforts and reducing environmental impact.

Lightweight: Aluminum alloys are significantly lighter than many other metals, making them ideal for applications where weight reduction is critical, such as aerospace and automotive industries.

Cost-Effective: Aluminum alloys often provide a cost-effective solution due to their durability, long lifespan, and ease of manufacturing.

Technical Specifications:

Aluminium/Copper Pellets 6mm max size:

Maximum Lump Size: 6mm.

Weight: 1g – 50g.

Aluminium/Silicon Powder spherical 150 micron max:

Maximum Particle Size: 150µm.

Product Shape: Spherical.

Production Method: Gas Atomised.

Particle Size D90:

Weight: 10g – 10000g.

5083 Aluminium alloy Foil 1mm thick:

Thickness: 1mm.

Diameter: 4mm – 15mm.

Size: 10mm x 10mm – 500mm x 500mm.

| Manufacturer | |

|---|---|

| Applications / Industries | , |

DIDN'T FIND WHAT YOU WERE LOOKING FOR?

Our team is here to help you! Call us or leave us a message and an Apel Laser consultant will be happy to answer your questions and find personalized solutions for you.