Blog

OPTICAL FIBRES

What Are Optical Fibers?

Optical Fibers are hair-thin strands of glass or plastic that transmit light over distances just like wires carry electricity. They’re used extensively in telecommunications, datacomm, laser beam delivery, sensing, medical applications, and more.

Fiber optics have had a huge impact on modern life. In fact, the words you’re reading right now were almost certainly transmitted through fiber optics during at least some of their journey from a web server to your device.

Beyond telecommunications, fiber optics are also used in many other ways, including laser beam delivery in surgical systems and high-power industrial laser systems. They are also components in navigational systems and sensing systems for buildings, bridges, and power plants. There are numerous other specialized uses, too.

Operating principles

A fiber optic cable functions in very much the same way as a water pipe. Light goes in one end and comes out the other. And, just like a water pipe, the path the fiber takes can be long – literally several kilometers – and can go through bends and curves. This property provides tremendous flexibility (literally!) in terms of the way fibers can be implemented in a system. Together with the ability to transmit light over even long distances with very low loss, this accounts for the widespread utilization and commercial success of fiber optics.

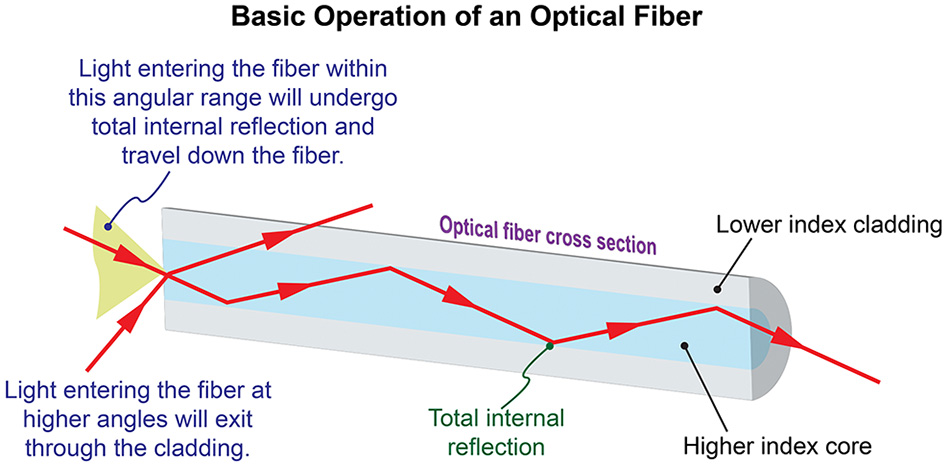

The underlying operating mechanism of an optical fiber is actually quite simple. The most basic optical fiber consists of a circular cross-section core surrounded by a second material, called the cladding, having a lower index of refraction.

Light introduced into one end of the fiber at the proper angle will travel through the core and stay contained within it until it emerges out the other end. This happens because of total internal reflection. This occurs when light traveling in a material encounters an interface to a second medium with a lower index of refraction. If the light hits the interface at a low enough angle it is completely reflected – none of the light escapes. Anyone who has looked up at the surface when underwater experiences the same phenomenon. You can see directly above you, but as you try look at the surface at angles far enough from straight up, you can’t see out.

Fiber types

Fiber optics can be classified by the markets they service, as well as by various performance or construction characteristics. The simplest grouping is by application; and that typically breaks down into telecommunications/datacomm and then everything else. That latter group is often referred to as “specialty fibers.” In terms of design and functionality, there are several different basic types of fibers, and countless design variations within those types, which are described below. Often, a fiber may belong to several of these groups. For example, a single-mode fiber may be polarization maintaining, and also ultrafast.

| Fiber types | Characteristics and Use |

| Single-mode | Single-mode fibers have a core diameter that is so small that only the lowest (and physically smallest) transverse mode can propagate. This impacts performance in several ways. For telecommunications applications, it reduces fiber attenuation and dispersion. This is why single-mode fiber is the most widely used type for long-haul telecommunications. The output of a single-mode fiber can be focused to the smallest possible spot size. This makes them useful for many scientific and industrial laser applications, particularly in the construction of fiber lasers. |

| Multi-mode | These have core diameters large enough to permit higher-order transverse modes to travel through the fiber. This typically enables them to transmit more optical power, but they also suffer from higher dispersion. They’re also typically less costly to manufacture than single-mode fibers. Together, these characteristics make them popular for short-haul datacomm applications. They’re also widely used for beam delivery with higher-power lasers in materials processing, surgical, and spectroscopic applications. |

| Polarization maintaining | Normally, birefringence within an optical fiber scrambles the input polarization as it travels down the cable. Polarization maintaining fiber is intended for applications where this isn’t desirable. This includes some high-end networking applications, laser amplifiers, IFOGs, and many sensing systems. Polarization maintaining fibers aren’t designed to eliminate birefringence. Instead, they are single-mode fibers constructed to maximize it in a very specific way. The result is that power doesn’t couple from one polarization state to the other as it propagates; this maintains the input state of polarization. |

| Sensing fibers | Sensing fibers is really a category based more on application than design, although these most frequently use a pure silica core construction. It’s also common for sensing fibers to utilize materials and designs which deliver a high degree of thermal, chemical, and hydrogen resistance. Most fiber sensors for temperature, pressure, flow, acoustics, and strain are based on signals derived from Brillouin or Rayleigh scattering along the length of the fiber, or from Fiber Bragg Gratings (FBGs) embedded at specific locations. |

| Laser and amplifier | These are “active fibers” that form the basis of fiber lasers and several other types of light amplifiers. They incorporate a dopant to produce laser action (light amplification) along the fiber length. Usually, pump light is coupled into the cladding, and this energy is used to amplify seed light introduced into the fiber end. It’s common for them to be produced with an accompanying passive beam delivery fiber which is specially matched to the active fiber. The passive fiber maintains the optical characteristics of the light from the active fiber and provides the highest possible transmission and power handling capabilities – often well into the multi-kW level. |

| Ultrafast | This includes both active and passive fibers specifically designed for use with short pulsewidths and high peak powers. Applications include ultrafast fiber lasers, chirped pulse amplification, narrow linewidth amplifiers, and frequency doubling. There are many different design forms for ultrafast fibers depending upon the specific use. But they all commonly require tight polarization and dispersion control, high beam quality, and low photodarkening. |

How are fiber optics made?

A single fiber optic cable that might be kilometers long starts out as a glass tube of only a meter or two in length. A chemical process is used to transform the material on the inside diameter of the tube and increase its refractive index. Then, the tube is collapsed down into a solid cylinder, and piece from the center of this rod is cut out to make what is called a preform.

The preform is placed into a drawing tower. It’s heated until it softens and then end is pulled to form a thin strand. The strand is continuously wound over pullies to produce the cable. A polymer coating is applied to the outside of the fiber during this process. This will make the finished fiber more robust and easier to handle.

Some optical fibers are not circularly symmetric. An example of this would be “panda” type polarization maintaining fibers. A more complex series of steps are used to build the preforms for these types of fibers.

Coherent offers an extensive and diverse range of specialty fibers including laser and amplifier fibers, high-power laser beam delivery fibers, fibers optimized for medical applications, fibers for sensing applications, and much more. We can customize fibers to meet specific customer needs and integrate them into fiber assemblies, including connectors, optics, and more.