APEX 400 Press | High Throughput XRF Hydraulic Press

The APEX 400 hydraulic press is dedicated to the production of pressed pellets for XRF laboratories and other elemental analyses. It is a benchtop press designed for repeated use in high-throughput analytical testing environments, producing sample pellets in steel rings, aluminium cups, or as unsupported pellets.

- Compact, benchtop press: Suitable for all laboratories, even where space is limited.

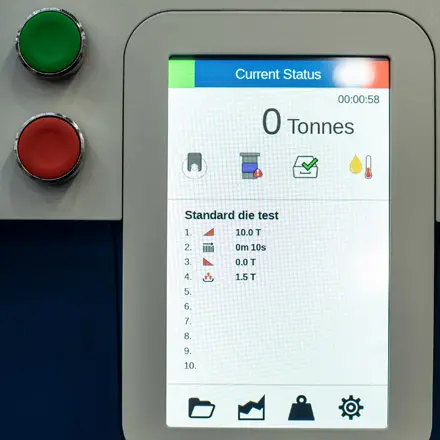

- Fully automatic and programmable pressing cycles: Automated processes streamline your workflow and free your team to work on other tasks.

- Quickshift Technology for automatic pellet extraction: When pressing pellets without steel supporting rings, the pressing platen switches automatically between pressing and extraction modes.

- Supports use of ring dies and standard dies: Specac’s first press to support ring dies, for both 51.5 x 35 mm rings and 40 x 32 mm rings, as well as standard dies of 32 and 40 mm diameters.

Resources:

The APEX 400 pellet press is designed for use in busy on-site testing laboratories at mining, manufacturing, and other material testing facilities. It has several features designed to automate the pressing cycle, including ‘Quickshift’ technology, which automatically moves the pressure plate between load and release positions to remove the pellet from the pellet die without manual intervention.

Specifications

- Rated maximum load: 400 kN (40 t)

- Dimensions: W 462 mm x D 346 mm x H 573 mm (W 18.2″ x D 13.6″ x H 22.5″)

- Weight (uncrated): 120 kg (265 lbs)

- Power: single phase, universal power supply

| Manufacturer |

|---|

Related products

DIDN'T FIND WHAT YOU WERE LOOKING FOR?

Our team is here to help you! Call us or leave us a message and an Apel Laser consultant will be happy to answer your questions and find personalized solutions for you.